When you hear the word riveting, it may not ring a bell, but riveting is all around you.

We created this page in the hope that you can learn more about riveting.

About Riveting

What is riveting?

Riveting has a long history and was used in ancient armor.

There are many different types of rivets, from small to large, that we can find in our daily lives.

Types of Rivets

Rivets can be divided into three main categories depending on the method of riveting.

This riveting method is used when the work can be done from only one side.

Pulling the nail-like shaft toward the operator deforms the inside of the cylindrical rivet and secures it in place.

Since the connecting pressure is determined by the breaking strength of the shaft, it is weaker than other riveting methods with the same rivet diameter.

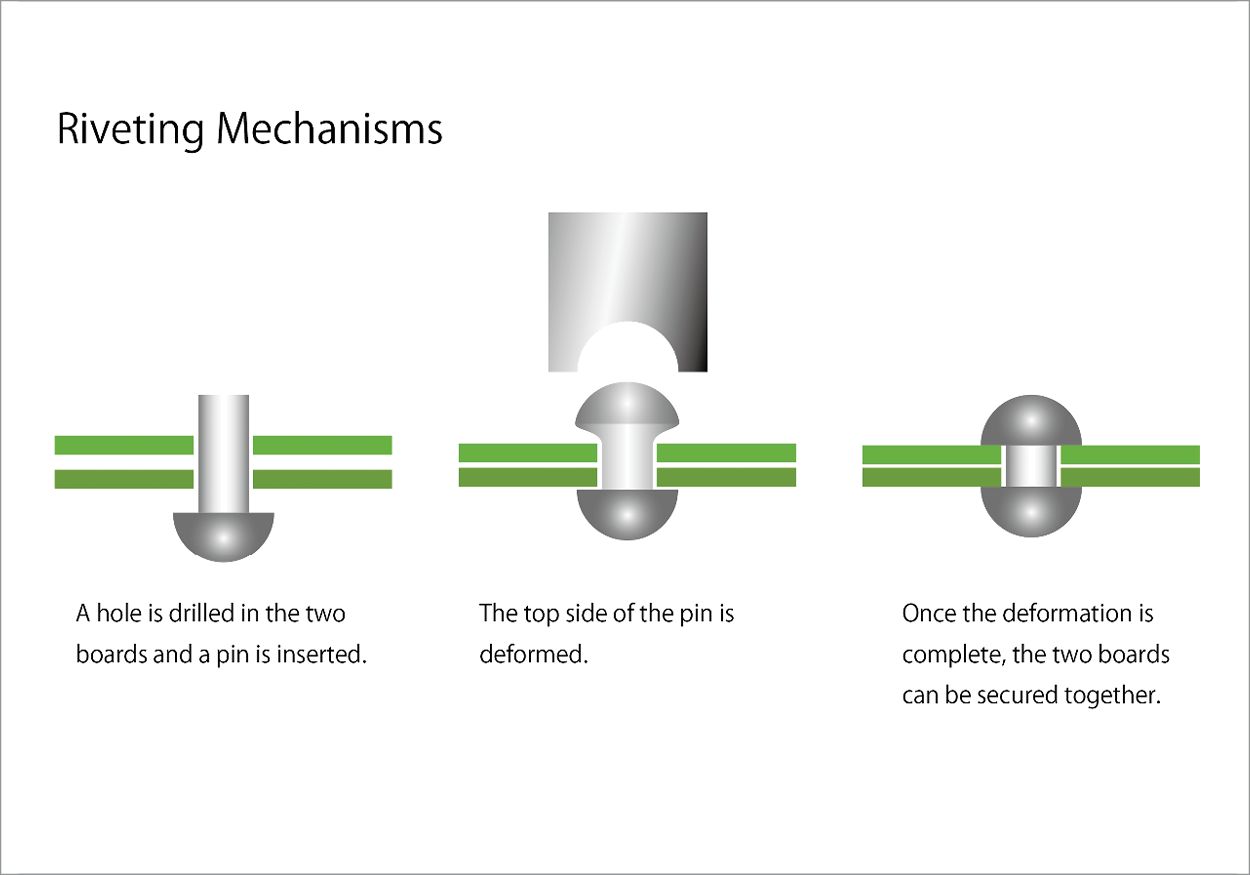

A large amount of pressure is applied from the axial direction of the rivet to deform the rivet and bind the parts together.

Since the entire rivet is crushed, the rivet shaft becomes thicker and there is no gap between the rivet and the part, allowing for strong binding. However, this is not suitable for links that require movement.

In addition, the rivets are crushed by the strong pressure, which causes loud vibrations and noises during processing.

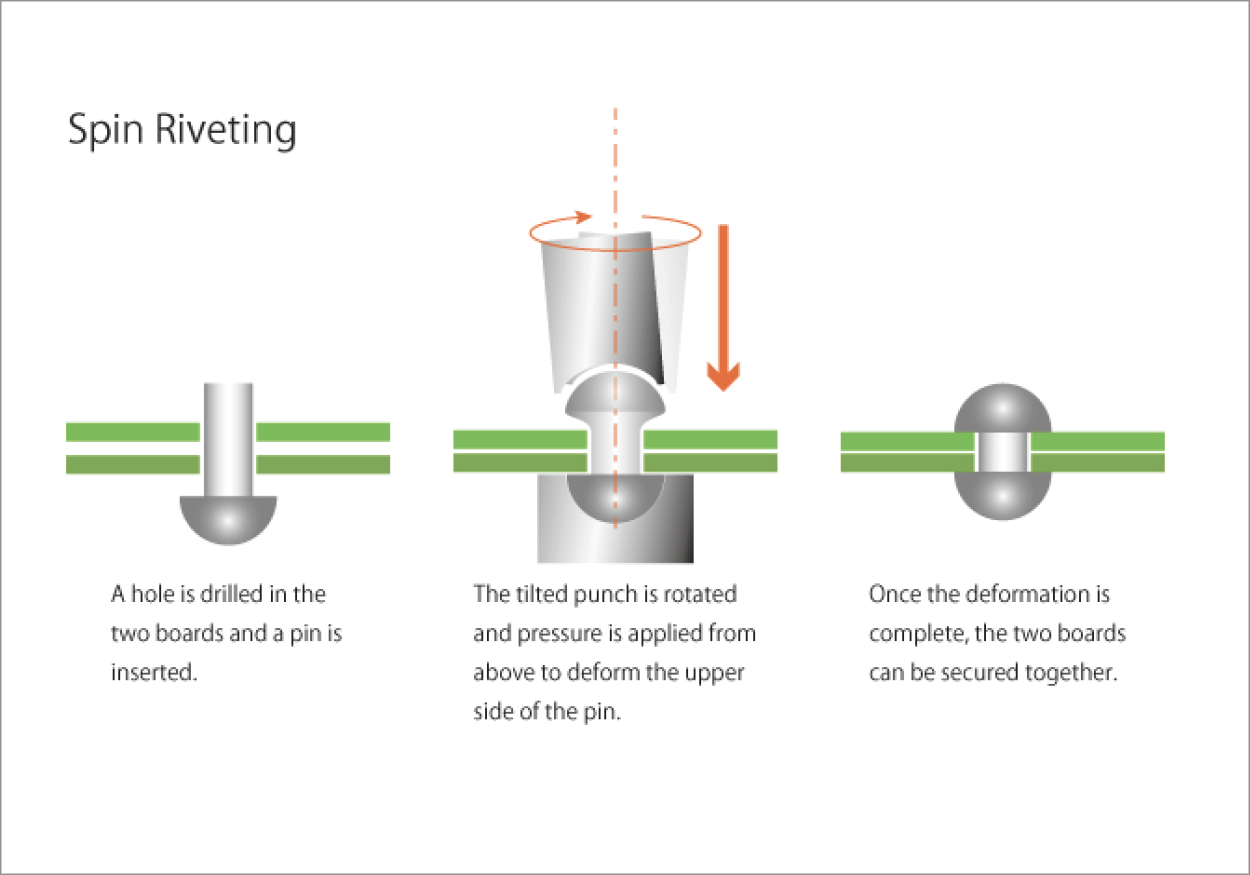

The rivets are deformed and joined together by applying pressure while rotating.

Since the rivet is deformed by weak pressure, the rivet shaft is less likely to become thicker and is used to join parts such as hinges that require mobility.

Compared to press riveting, which rivets only by applying pressure, the rivets are more suitable for delicate products and work that requires precision because they can be significantly deformed with an extremely low amount of force.

About Riveters

Riveting Machines

Machines which carry out riveting are called riveters.

This machine is used to crush the rivet heads and hold materials in place.

There are various riveting machines depending on how the rivet head is crushed.

There are three types of the earlier mentioned spin riveting machines: servo (electric), pneumatic and hydraulic.

We manufacture servo (electric) riveting machines and pneumatic riveting machines.

Spin Riveting Machines and Press Riveting Machines

Press riveting applies a strong force from one direction to deform the rivet.

Because of the strong pressure applied, loud vibrations and sounds are generated.

Also, the rivets have a thicker shaft and lose their play.

This is good if you want it to stay firmly in place, but not if you want mobility.

On the other hand, in spin riveting, the spin head, which is tilted several degrees from the rivet axis, applies pressure as it rotates, allowing the rivet to be deformed with less force than in the press type.

Compared to press riveting, the rivets are subjected to less than 1/7th of the force and there is less shock, vibration and pressure applied to the product and rivets themselves, so unnecessary deformation is less likely to occur and precision work can be performed.

The rivet shaft can also be deformed by pressure to make it thicker, producing excellent results with a wide range of protection.

| Press Riveting | Spin Riveting | |

|---|---|---|

| Riveting Methods | The rivet is crushed from above with the press. | An angularly mounted special tool is pressed against the rivet while rotating to press and shape them. |

| Speed | ◎ Fast |

〇 Slower than the press type |

| Cost | ◎ Fast |

More expensive than the press type |

| Major Applications | Fixing and joining of clothing, housing equipment, electronic components, and more. | Joining of automobile and, aircraft parts, machine tools for electrical products, medical equipment, and more. |

| Damage to work pieces | Significant | Insignificant (1/7th that of the press type) |

About Spin Riveting Machines

It’s amazing what a spin riveting machine can do!

Feature 1 Riveting motor shafts

Extra deformation is a serious problem, as it can lead to unwanted noises.

The spin riveting machine that gently carries out riveting even under such severe conditions continues to play an active role.

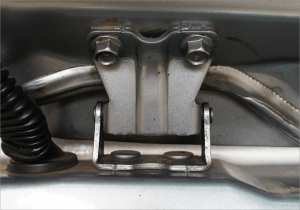

Feature 2 Hinges for stable movement

Deformation of the hinge shaft during riveting disables stable hinge movement.

Spin riveting, which uses weak force, can achieve stable riveting without causing unnecessary deformation to the parts.

Feature 3 Detailed Riveting

The mirror used at dental clinics is placed inside a stainless steel case and then softly and gently crimped from the edges to hold it in place.

The spin riveting machine doesn’t apply unnecessary impact, so mirrors can be riveted without breaking.

Spin Riveting Machine Comparison Chart

| Hydraulic Riveting Machines | Servo Riveting Machines (Koki Shokai) | Pneumatic Riveting Machines (Koki Shokai) | |

|---|---|---|---|

| Speed | △ Max. weight | ◎ Electronically controlled | ◎ Lightweight |

| Pressure | Excellent under high pressure | ◎ Low-high | Excellent for low-middle pressure |

| Price | 〇 | 〇 | ◎ |

| Functions | 〇 | ◎ Can be equipped with sensors | 〇 |

| Other | Customizable△ | Compatible with punch jigs ◎ | Compatible with punch jigs ◎ |